Top 10 UV Light Uses for Sterilization How Effective Is It?

UV light for sterilization has gained significant attention in recent years. Various studies indicate its effectiveness in killing bacteria and viruses. For instance, a report by the Centers for Disease Control and Prevention states that UVC light can eliminate up to 99.9% of pathogens in a controlled environment. This technology is increasingly employed in healthcare settings, proving vital for infection control.

Despite its benefits, not all applications deliver consistent results. Factors like exposure time and distance from the surface influence efficacy. Some experts argue that additional methods may be necessary to ensure complete sterilization. The effectiveness of UV light also depends on the type of microorganisms present. For example, some resistant strains may require longer exposure.

As the world continues to grapple with emerging health threats, exploring UV light for sterilization appears promising. However, businesses and consumers must understand its limitations. Balancing UV light applications with other sterilization techniques can lead to better outcomes. Ongoing research will further clarify its role in maintaining hygienic environments.

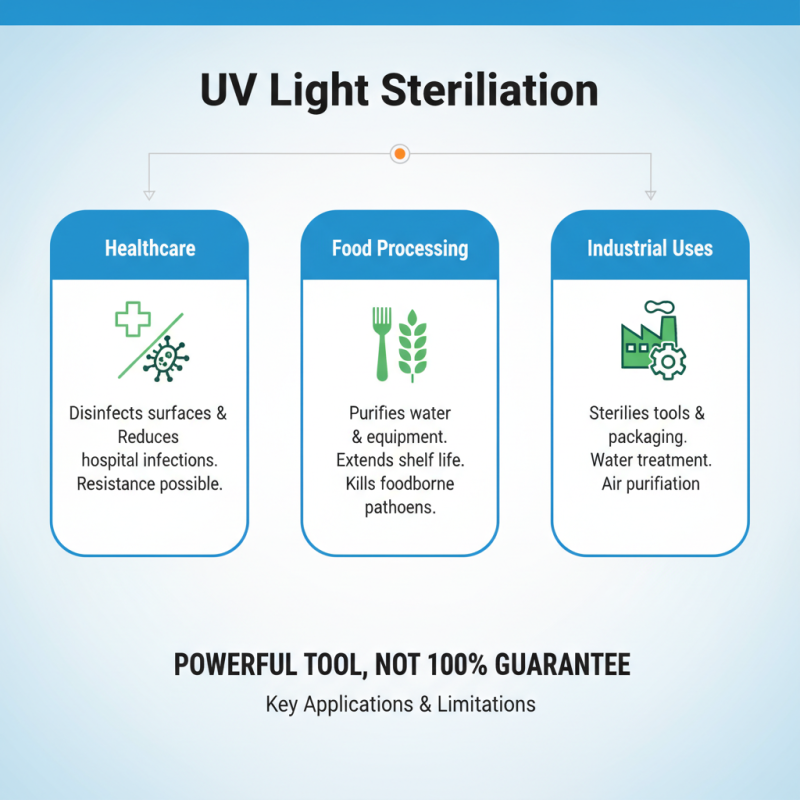

Applications of UV Light in Sterilization across Various Industries

UV light has emerged as a powerful tool for sterilization in various industries. Its applications span from healthcare settings to food processing facilities. In hospitals, UV light effectively disinfects surfaces and air. It reduces the risk of hospital-acquired infections, but complete sterilization is not always guaranteed. Some pathogens may resist UV exposure.

In the food industry, UV light sanitizes equipment and extends shelf life. Many companies adopt this method for its non-chemical nature. However, proper intensity and exposure time are crucial; otherwise, not all bacteria are eradicated. Some may thrive if the process is not closely monitored. Additionally, UV light can be harmful to human skin and eyes, which limits its application in certain environments.

Water treatment facilities also utilize UV light. It disinfects drinking water by inactivating harmful microorganisms. Yet, the effectiveness can vary based on water clarity and flow rate. Users need to ensure that their systems are optimized. Without careful management, the advantages can diminish. Industry professionals must continuously evaluate the balance between efficiency and safety in UV sterilization.

Mechanisms of Action: How UV Light Kills Microorganisms Effectively

Ultraviolet (UV) light has gained attention for its ability to eliminate microorganisms effectively. This technology operates primarily by damaging the DNA or RNA of harmful pathogens. When exposed to UV light, the genetic material absorbs energy. This absorption results in the formation of dimers, which disrupts normal cellular function. As a result, the microorganisms cannot replicate, leading to their inactivation.

The efficiency of UV light is influenced by several factors. The intensity and wavelength of the light are crucial. UV-C, specifically between 200 to 280 nanometers, is the most effective for sterilization. However, the distance between the light source and the target surface plays a significant role. If the surface is dirty or covered with organic matter, the effectiveness of UV sterilization decreases.

While UV light can be a powerful tool, it is not infallible. Some microorganisms have developed resistance, and shadows can prevent effective exposure. Regular maintenance and recalibration of UV equipment are necessary to ensure its effectiveness. Continuous research is needed to fully understand the limitations and best practices for using UV light in sterilization.

Comparative Efficacy: UV Light vs. Traditional Sterilization Methods

UV light has emerged as a popular method for sterilization, especially in recent years. It works by damaging the DNA of microorganisms, rendering them unable to reproduce. In comparison, traditional sterilization methods, like heat or chemicals, can be less efficient in certain contexts. For example, heat requires time and specific temperatures, while chemicals can leave residues. Each method has its strengths and weaknesses.

When considering effectiveness, UV light offers rapid sterilization. However, it may not penetrate surfaces as deeply as heat or chemicals. Shadows and barriers can limit its reach. Thus, it’s vital to ensure that the area is well-exposed to UV light for optimal results. A tip for effective use is to rotate objects when using UV light, maximizing exposure on all surfaces.

It is essential to remember that UV light can be harmful to humans. Protective equipment, like goggles and gloves, is crucial when operating UV sterilization tools. Additionally, always monitor the sterilization duration. Too little time can lead to insufficient disinfection, while excessive exposure can cause damage. Reflect on these points when choosing the right sterilization method for your needs.

Safety Guidelines and Precautions for Using UV Light Sterilization

When using UV light for sterilization, safety is paramount. UV light can be harmful to skin and eyes. The Centers for Disease Control and Prevention (CDC) recommends wearing protective gear, such as goggles and gloves. It is essential to limit direct exposure. Prolonged contact can lead to burns or vision damage.

Proper use of UV sterilization devices involves specific guidelines. Research indicates UV-C light is effective against bacteria and viruses, achieving over 99.9% reduction rates in controlled environments. However, studies show that efficiency declines with distance and obstruction. Maintaining the recommended distance ensures optimal effectiveness.

Regular maintenance of UV equipment is necessary. Dust and contaminants can reduce UV output. Safe operation requires a clean environment. Additionally, UV light should not replace traditional cleaning methods. It's most effective as a supplementary tool. Continuous education on UV safety practices is critical for workplaces. Ignoring these guidelines can lead to accidents or ineffective sterilization.

Top 10 UV Light Uses for Sterilization - Effectiveness, Safety Guidelines, and Precautions

| Use Case | Effectiveness (%) | Safety Guidelines | Precautions |

|---|---|---|---|

| Water Purification | 99.9% | Ensure water is clear for optimal UV penetration. | Avoid direct exposure to skin. |

| Surface Disinfection | 99.9% | Clean surface before application. | Wear protective eyewear. |

| Air Purification | 95% | Install in well-ventilated areas. | Ensure the unit is properly shielded. |

| Healthcare Equipment | 99.9% | Follow manufacturer's guidelines. | Only use on compatible materials. |

| Food Safety | 98% | Use approved UV-C systems. | Do not use on oily foods. |

| Laboratories | 99.9% | Keep work area clean. | Do not expose skin or eyes. |

| Wastewater Treatment | 90% | Monitor UV intensity regularly. | Install UV shields for safety. |

| HVAC Systems | 95% | Service regularly for efficiency. | Avoid direct contact with UV lamps. |

| Personal Protective Equipment (PPE) | 99% | Use appropriate PPE during check. | Inspect for damage before use. |

| Public Spaces | 98% | Follow local regulations for use. | Keep people out of treated areas. |

Future Trends: Innovations in UV Sterilization Technology and Uses

As the demand for effective sterilization continues to grow, UV sterilization technology is evolving rapidly. Innovations are emerging, focusing on more efficient applications in various settings. For instance, recent developments in UV-C light sources offer stronger germicidal effects while being energy-efficient. The creation of portable UV sterilizers also makes it easier for users to sanitize small spaces effectively.

Tips: Always follow the manufacturer's guidelines when using UV devices. Proper distance to the surface is critical for effective sterilization.

New trends include integrating UV technology with smart systems. This allows for real-time monitoring and adjustment in response to changing environments. Additionally, innovations in UV coatings can help protect surfaces from microbial growth, which is especially useful in high-touch areas.

Tips: Consider combining UV sterilization with other cleaning methods for enhanced protection. Regular maintenance of the UV devices is essential to maximize performance and effectiveness.

While promising, these technologies require careful handling. Overexposure to UV light can pose risks to skin and eyes. Ensuring safety measures are in place is crucial for users. Balancing benefits with potential hazards is vital in implementing these technologies effectively.

This website uses cookies to ensure you get the best experience on our website. Learn More

ACCEPT